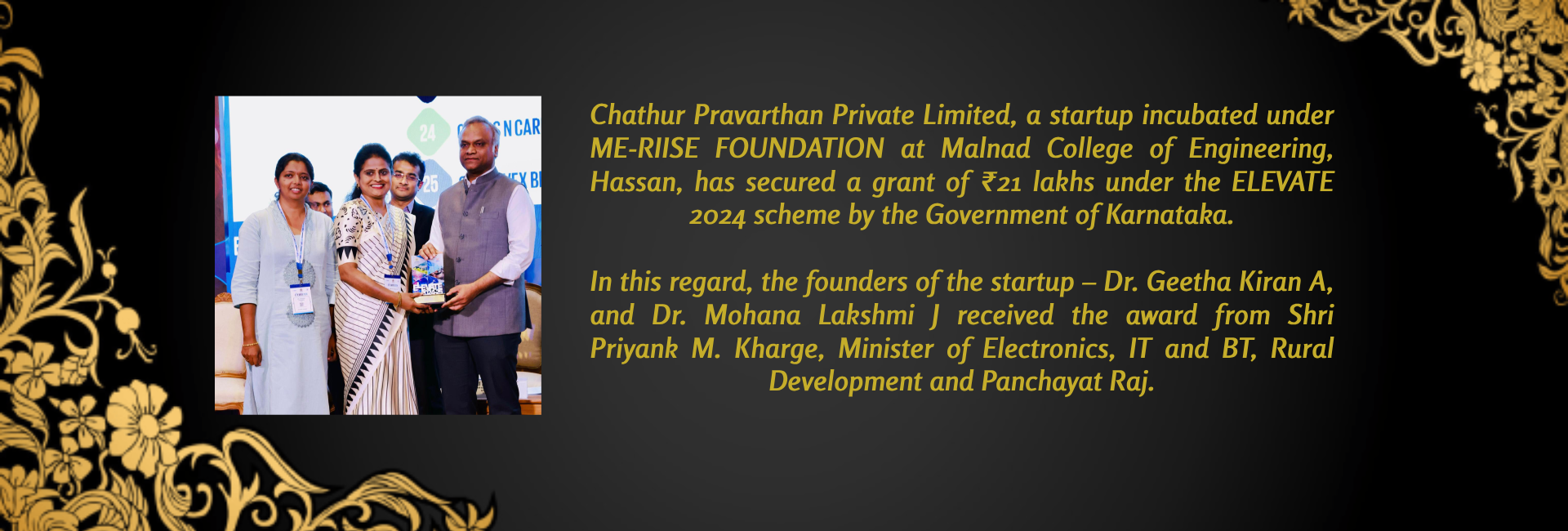

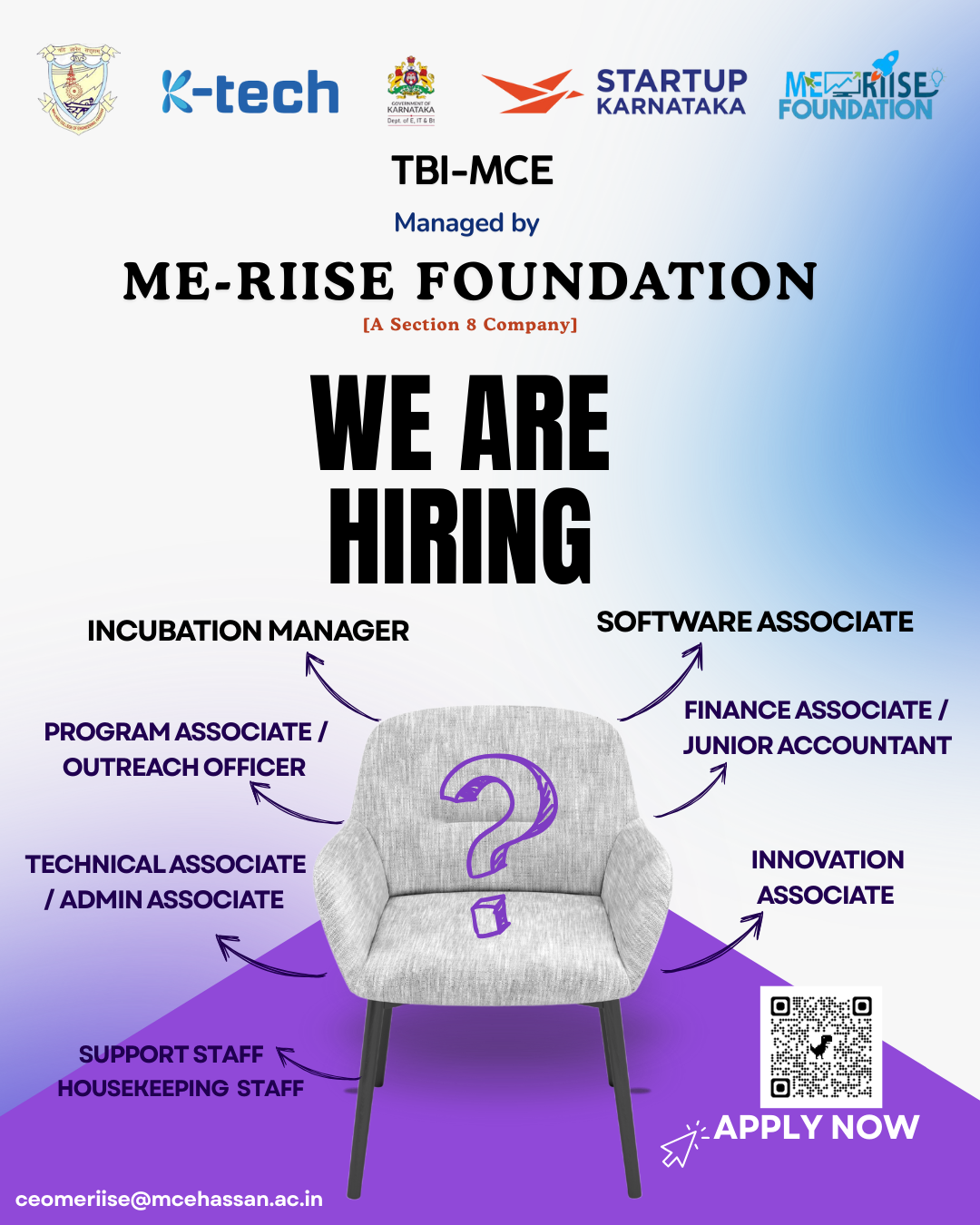

ME-RIISE Foundation

ME-RIISE was formed by MCE in the year 2018 supported by Management, Teaching staff and Students.

Join us NowAwards, Medals, Patents & RECOGNITION

Technical events guide engineering students, computer engineers, researchers to dream bigger and achieve them.

Read MorePlacements

The department of Training and Placement, established during the early nineties, has a full-fledged office in the campus.

Check NowStudent Clubs

Club or a society helps you to gain knowledge, skills and experience in leadership, communication, problem-solving.

Contact Now

M D Ranganath is the Former Chief Financial Officer(CFO) of Infosys, a top leading IT company. He completed his Bachelor of Engineering in the year 1984 at MCE, Hassan.